Protective Coating Systems

Anti-carbonation coatings

Anti-carbonation coatings are surface treatments that have a high resistance to carbon dioxide. They protect concrete from carbonation by acting as a carbon dioxide barrier.

Usage areas :

• Bridges, Flyovers, Aqueducts, viaducts

• Residential & Commercial Buildings

• Multi storey car parks & podiums

• Chimneys, cooling towers and silos.

• Jetties and berths.

• Overhead water tanks.

• Industrial buildings and power plants

Anti-Corrosion Coating

Anti-corrosion coatings protect metal components against degradation due to moisture, salt spray, oxidation, or exposure to a variety of environmental or industrial chemicals in a range of industries. Anti-corrosion coatings allow for added protection of metal surfaces and acts as a barrier to inhibit the contact between chemical compounds or corrosive materials. In addition to corrosion prevention, many of the coatings listed below also provide a bonus of abrasion resistance, non-stick performance, and chemical protection.

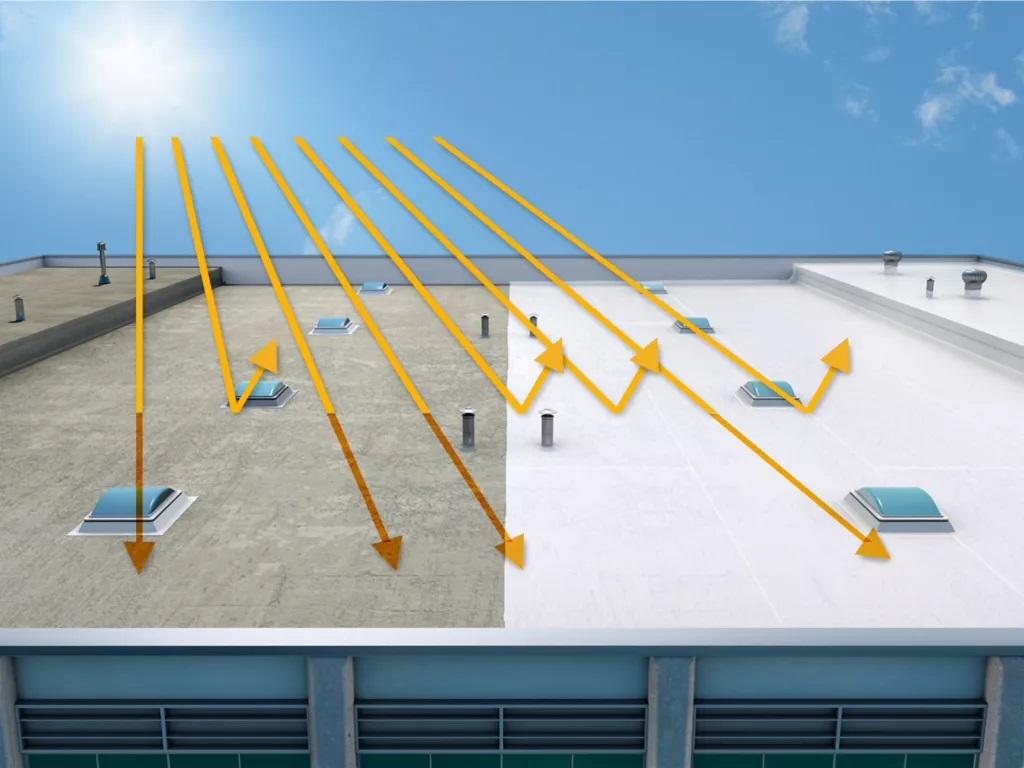

Heat Reflection Coating

Heat reflection Coating is an outdoor coating system, especially for roof tops, concrete or steel, applied to reflect solar heat, thus bringing down the roof temperature by 15-20oC depending on hot summers, thereby resulting in the drop in indoor ambient temperature by 4-8oC.

Using Areas : All residential and commercial buildings

Exterior Wall Protection Coating

The moisture retention, or water seepage, can in turn damage the structural integrity of exterior wall. Hence, the transparent waterproofing coating will effectively prevent cracks and thus avoid damage due to seepage and pressure.

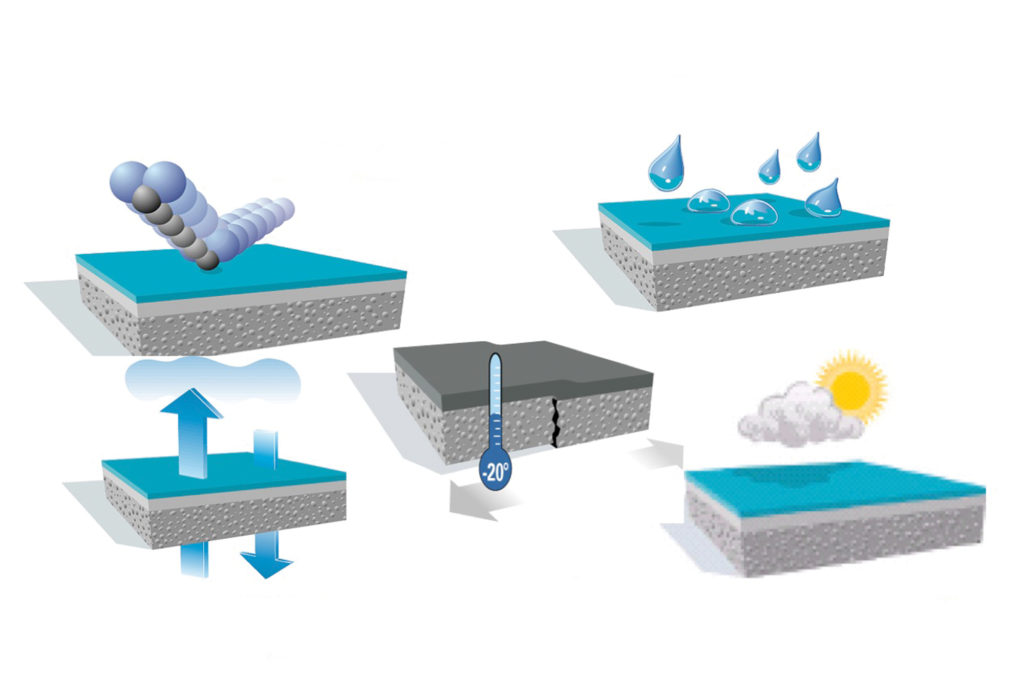

Benefits of Protection coatings:

▪ Breathable – Very Important

▪ Water based- Can apply of damp surface.

▪ Excellent Resistance to UV.

▪ No degradation or chalking.

▪ Penetrates into the pore structure

▪ Good Adhesion to substrate.

▪ Excellent Elongation – to withstand internal stresses

Coal Tar Epoxy Coating

Coal tar epoxy consists of epoxy resins and coal tar. It is a type of polymer used to coat surfaces and protect them from corrosive environments. It is primarily used on metal and concrete in tough settings like industrial and offshore operations, where chemicals, saltwater and other substances can cause deterioration.

Usage Areas :

• MS/concrete pipes and metallic structures

• Crude oil storage tanks

• Underground structures

• Steel structures pipes

• Dams

• Barrage gates.

• Penstocks

• Foundation walls

• Sumps

• Concrete and steel surfaces in sewage treatment plant

• Paper mills / chemical plants

Polyurea Coating

Polyurea is a waterproofing material that is often used in industrial and commercial settings to protect surfaces from water damage. It is applied as a liquid coating, which then quickly cures to form a durable, waterproof barrier.

USAGE AREAS:

waterproofing roofs,

Foundations, decks, and other surfaces.

Water Repellent Coating

Water-repellent coatings are the next step up from water-resistant coatings. Devices labelled as water-repellent have properties that repel water from them, which makes them hydrophobic. Water-repellent devices have a better chance of surviving a watery encounter.

USAGE AREAS:

Bricks, clay pavers, pattern paving, concrete, masonry, pebble finishes, sandstone, slate, unglazed tiles and primed metal surfaces.